Interviews • 01 Oct 2021

Interviewing Jack Matthew Elam on his Wandering Hour Series

I recently caught up with young British independent watchmaker, Jack Matthew Elam to discuss his unconventional path to watchmaking, his inspirations and his upcoming Wandering Hour Series. Jack is one of a handful of emerging British watchmakers who, inspired by Dr George Daniels and Roger W. Smith, decided to pursue independent artisanal watchmaking.

David Morris: How did you end up a watchmaker?

Jack Elam: My dad is an engineer, so I’ve always been familiar with working with my hands. For me personally, I gravitated more towards furniture making at the start. Before watchmaking, I did fine furniture and cabinet making at college and university. Creatively it was great, but intellectually it wasn’t stimulating me enough. So, after that, I tried loads of different things. Because no one in my family was in watchmaking or even wore watches, I wasn’t lucky enough to have been introduced to this world at a younger age.

I was around 22 years old when I first discovered watchmaking. I didn’t know watches were still made by hand back then, so discovering the likes of George Daniels and Roger Smith was quite remarkable. Netflix was probably wondering why I watched A Watchmakers Apprentice so many times [laughs]. My first literary introduction was Watchmaking by George Daniels, this was my first look into the mechanical side, then Theory of Horology and many other books followed. I was self-studying for two years before I found out there were schools in the U.K. that catered to this discipline.

Initially, I applied to the British School of Watchmaking in Manchester and was accepted to take part in their assessment day. But it became apparent during the interview that their focus – and that of the WOSTEP – was on watch servicing. Since this didn’t suit or line up with my goals, they recommended the Birmingham City University course to me. So, I applied and got an unconditional offer there, I started that course in September 2017. Ever since I discovered this art at 22 it’s been an obsession. Day and night, this is what I do now.

DM: Can you elaborate on your studies at Birmingham?

JE: In the first year, the focus is on both clocks and watches. At the Birmingham School, we covered the history of horology, mechanical watches and clocks, quartz watches, CAD, design work and business. It’s a 3-year course, In the 1st year, about 60% is self-directed study, we had 13 students to begin with in my year group; after a year, we lost four because of how difficult it was. The age range is skewing younger, which is nice to see. Young people are choosing to have a go and are sticking with it.

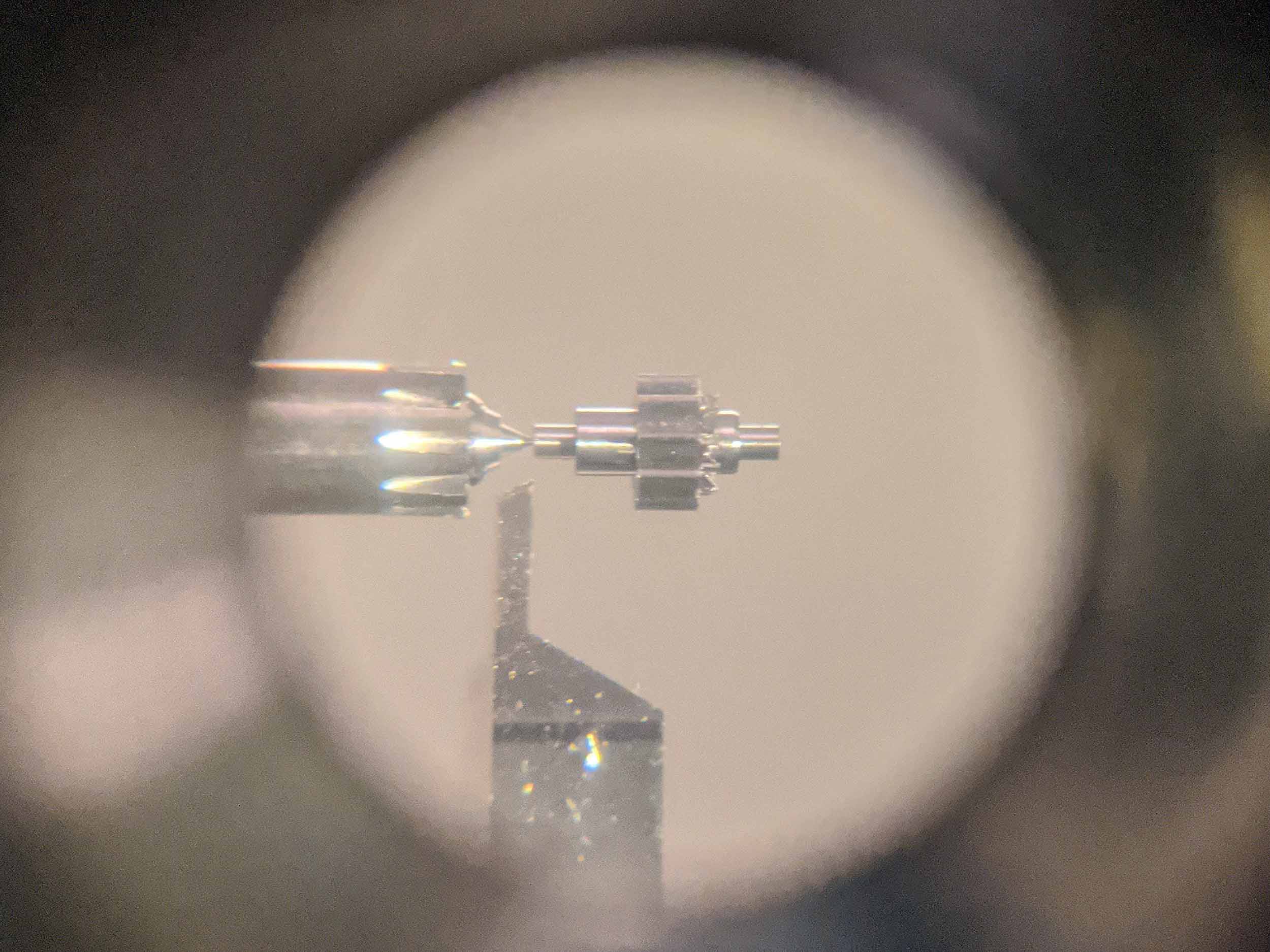

You don’t touch a watch until the end of the 1st year. At least that’s what it was like for my year group. Since then, it’s changed a bit, but you always start with a clock first; we had a Smith mantel clock with a rack strike movement. We also did hand skills like filing a brass cube to within 10-micron tolerances. The lathwork in the first year is with a hand graver, you don’t use a cross-slide until the 2nd year. Our first practical making was called the “mini clock project” similar in design to a carriage clock, the project consists of making the plates, pillars, screw, washers, you also make the recoil escapement where you make your own fly cutter based on the CAD drawings you do of the escapement, as well as make a few other components for it.

My school differed from the other courses because the first and second year are designed to prepare you for the third-year project, which you design in your second year. I designed a tourbillon wristwatch to make, but unfortunately, due to COVID closing the school at the start of 2020, myself and the rest of my year group was unable to finish our projects as our time was cut a few months short.

Since graduating I’ve registered my own company, and going down the route of an independent watchmaker. I have been furnishing my workshop with equipment and getting ready to start manufacturing my first series of wristwatches.

DM: Equipment can be quite a hurdle for young watchmakers.

JE: Yes, it’s costly. I did the BHI exams alongside my degree. With the George Daniels Educational Trust, they provided a scheme with my school, which if you pass those exams, they give you an achievement award. I won awards and got the best marks for servicing and won other funds for other exams as well. That definitely helps in establishing yourself, because there’s a lot of machinery required to make watches by hand, and none of it is cheap. I also took out a start up business loan to help acquire the equipment I have now.

DM: Which watchmakers have inspired you in your journey to be independent?

JE: I’m inspired by George Daniels, Roger W. Smith and Vianney Halter. F.P. Journe is also a big inspiration. I’m drawn to AkriviA for the level of the invention on display and for their design language, especially the Chronomètre Contemporain.

During my studies at Birmingham, we weren’t just limited to modern horology. We’d take inspiration from Harrison, Graham and all the greats from the past.

DM: Harrison and woodworking. We’re going full circle!

JE: [Laughs]. I could make a wooden clock if I wanted to. I grew up with woodworking and got my first toolset when I was 8. I did that at college and got fast-tracked because I progressed fast. After that, I was chosen to represent the Northwest of England in the National Skill Competition at the NEC, which ties in nicely because I did the NEC for furniture making, and then I was asked again to do it for watchmaking with The British Horological Institute.

DM: Let’s talk about your Wandering Hour Series.

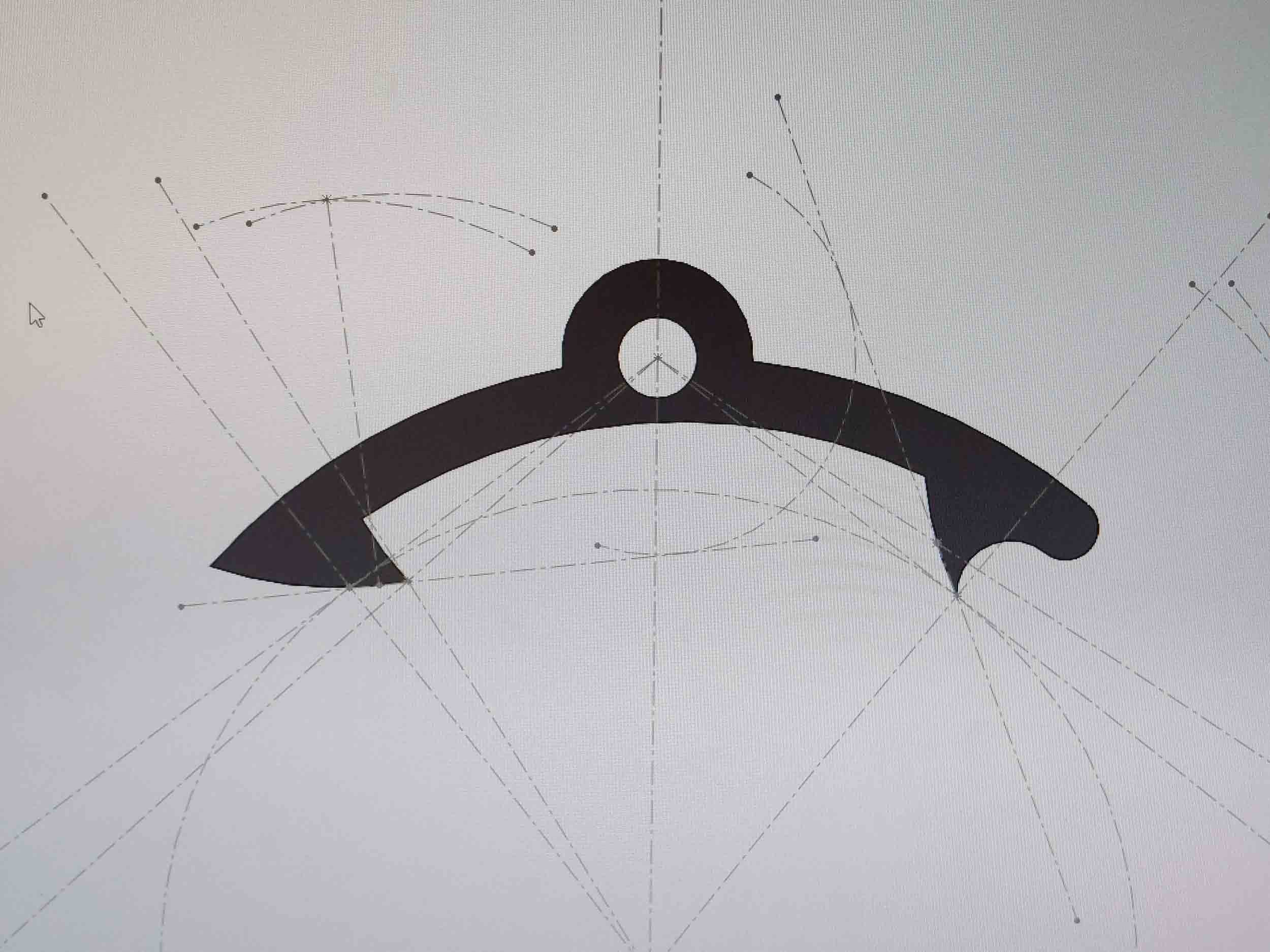

JE: Designing this watch was a bit different to how I’d design watches before. For this series, I’m using a BNB Concept calibre as the base movement which I’ve re-engineered and redesigned. BNB concept was a movement manufacture that the likes of Akrivia used at the start, so I feel in good company using this as the base for my first series.

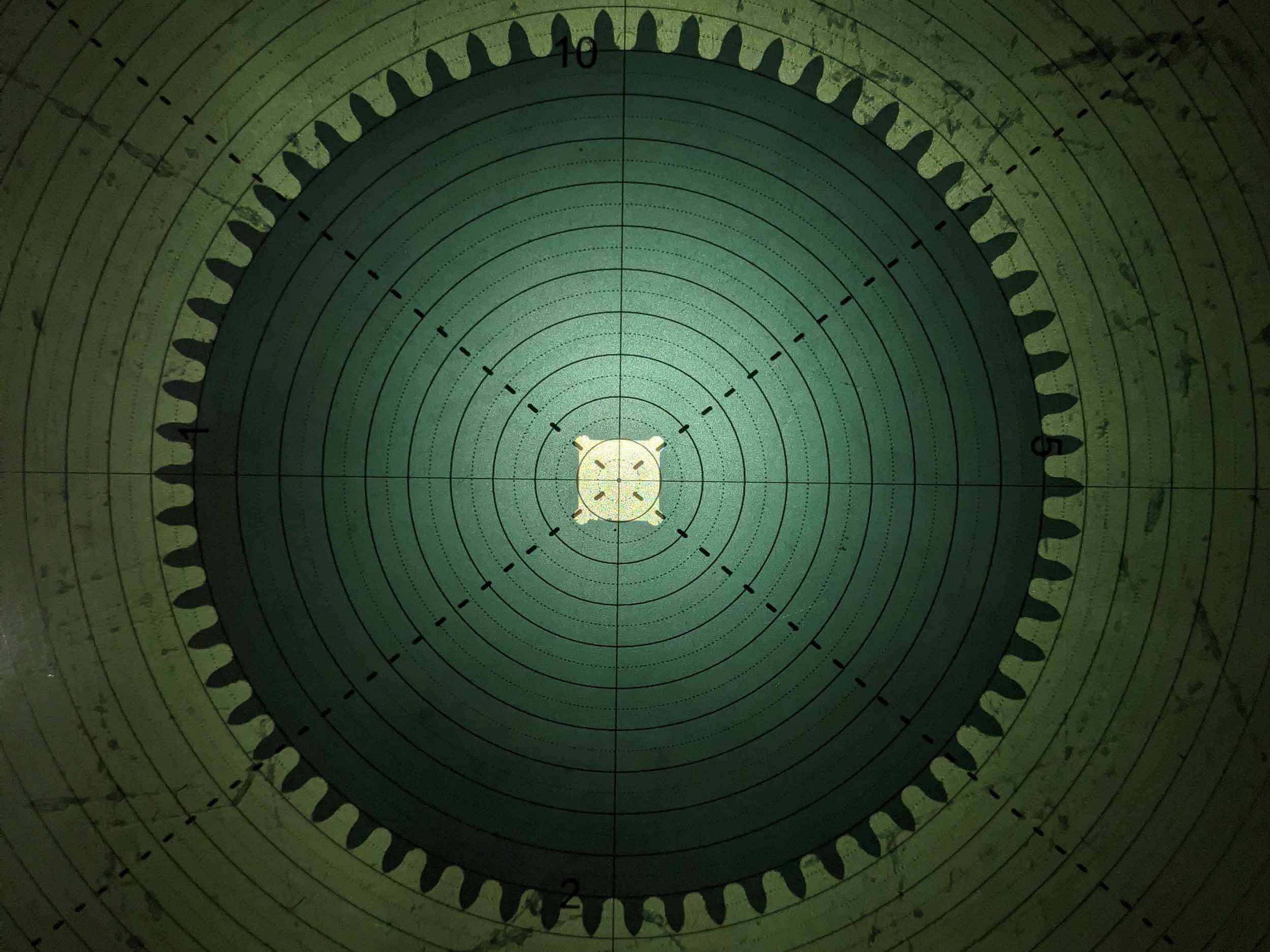

I am making my own main plates and bridges etc for the movement. For this series complication, I’ve designed a wandering hour module, which I will be making 90% of the components for. The Wandering Hour Series will have a power-reserve of 12 days and will be visible via a central power-reserve indicator on the dial side of the watch.

DM: Do you list Luc Monnet as an inspiration?

JE: Yes, I talk to Luc Monnet quite a bit, and he made a wondering hour complication for a pocket watch, using a 6498 as the base calibre. It is a beautiful piece. I list Luc as an inspiration as he has been a massive influence on me, he has also created some of the equipment I have in my workshop. My wondering hour is inspired by Luc Monnet’s pocket watch but with a contemporary flair and a design that is representational of my own DNA.

DM: Yes, you’re right. It’s nuanced in its traditional inspiration and contemporary styling.

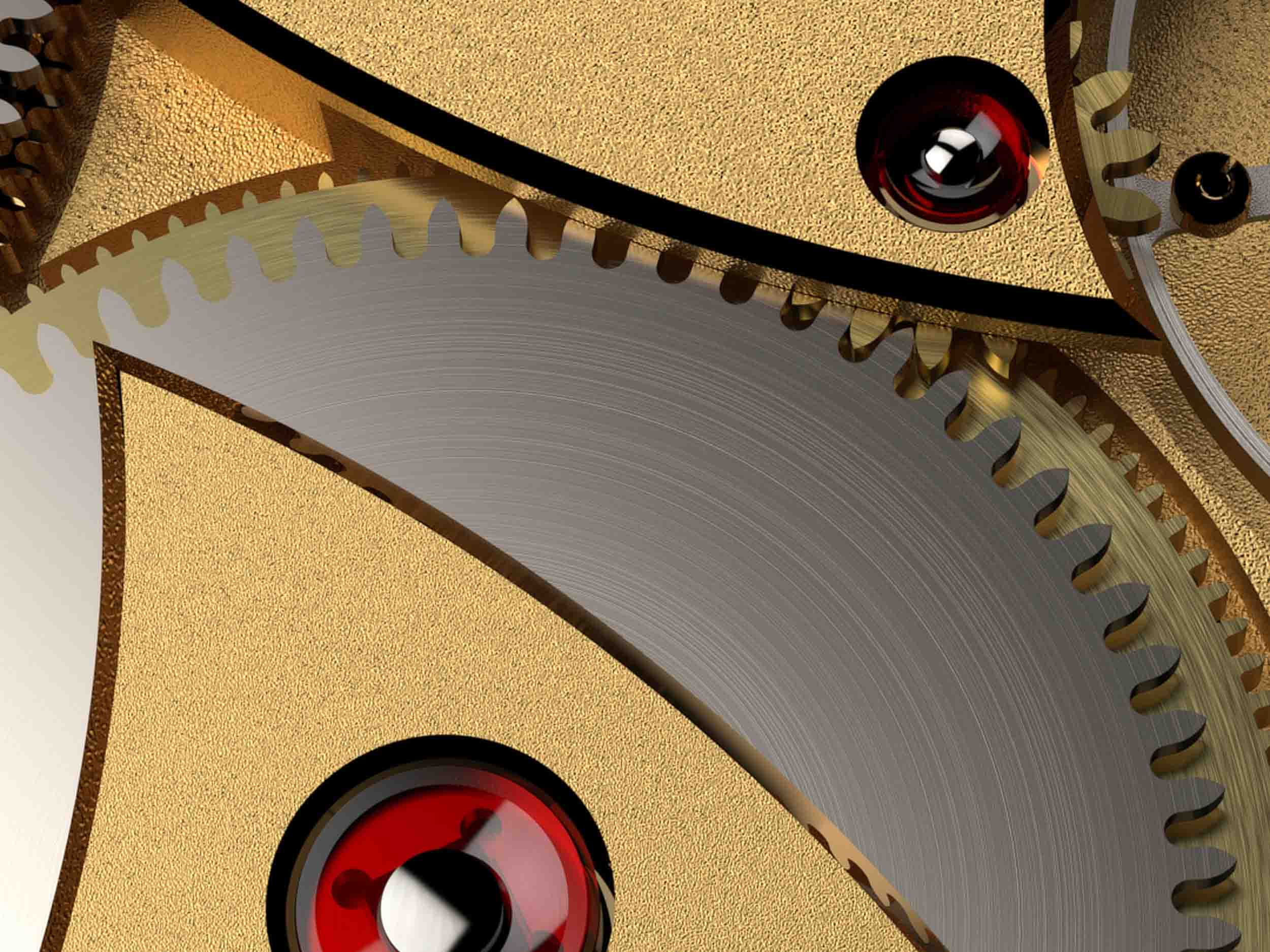

JE: The finishing is going to be quite British. On the other hand, the inspiration for the bridges is like the flow of water. When designing these bridges, the space between them was just as important as the bridges themselves.

And then, for the location of the balance wheel, you have a larger opening, like the water coming together forming a pool. It was essential to have a sense of balance.

DM: The flow has a particular calligraphic effect and is very organic. I see the influence of your previous work in woodworking.

JE: During the design process, I started with the shape of the negative space and then worked around that. The shape of the bridges comes from this approach.

Because I liked the flow of the negative space, I couldn’t bring myself to put a bridge or cock where the differential wheel is. So, I left that visible by using a sapphire disc which contains the gold chaton for the jewel, to impart a greater sense of balance. This sense of balance comes from nature. When I was working on furniture, I was more inspired by architecture, like churches and cathedrals. For my watches, you can still see elements of gothic architecture, but there’s that organic influence.

DM: What about the finishing?

JE: The wandering hour module is black rhodium plated with a black rhodium Clous de Paris central area. On the movement side the bridges are frosted, and gold plated with polished bevelled edges and black polished steel components. There are three separate finishing styles on the bridges, frosted, polished bevels, and graining on the side, this is reminiscent of what you might find on an MB&F for example and lends itself to a high level of attention to detail. The balance wheel has a frosted finish on the spokes, straight-graining on top and polished rims. So, there are quite a few finishing techniques implemented on each component and the order they are completed in will be important as to not damage any of the finishing.

The minute track is going polished gold-plated and serves to contrast against the blue minute track board.

DM: The wandering hour remains quite elusive in the 21st century. So, I suppose comparison to the A.P. Star Wheel and Urwerk watches is inevitable?

JE: Yes, the A.P. Star Wheel and Urwerk watches definitely come to mind. Especially Urwerk, just because they’ve consistently released this complication over two decades. Unlike the AP Star Wheel discs, which flick over twice to arrive at the correct hour, each disc on my Wandering Hour Series will flick over just once, anti-clockwise at the 6 o’clock position. The case will also reflect modern sensibilities in stainless steel and is sized at 39mm.

It’ll be sized at 39mm and about 10mm thick. The A.P. Star Wheel is 36mm, which is relatively small in this day and age, especially for a satellite complication. The font on my series is half a millimetre bigger than on the AP Star Wheel to increase legibility. With smaller wandering hour watches, you’re left wondering what the time is! [laughs]

DM: Appreciate the transparency; it’s great to hear about the design process and your inspirations.

JE: I don’t believe in keeping things secretive and relying on smoke and mirrors to appeal to collectors. There’s going to be a point when these old masters move on, and all that they’ve learnt will be gone.

In this independent sector, you’ve got to be fresh. I’m trying to push my design DNA to be consistent across the various watches and complications I intend to design and create in the future. I want to have a unique DNA that’s readily recognisable at first glance, like Smith and Journe, which is why my watches will have little to no branding on them.

DM: To wrap things up, do you have any advice for other young watchmakers?

Try everything when you’re young. You’ve got to be your own worst critic and ask yourself, “how can you improve on this?” and “what can you do to improve on it?” Nothing is ever one hundred per cent right, and you’re never totally satisfied, especially in watchmaking.

DM: Thanks Jack, it’s been an enlightening chat.

For more on Jack M Elam visit his website, https://www.jmelamwatches.com/ and his Instagram