News • 02 Apr 2020

Panerai Sustainability Report

For a brand so closely aligned with the sea, it makes perfect sense that Officine Panerai should care about – and actively work towards – protecting Earth’s precious marine waters and surrounding environments. The watchmaker has enjoyed a long history as one of the most iconic diving watch brands, given its heritage as the official timepiece supplier for the Royal Italian Navy. So now, in a world where both oceans and terrestrial environments are facing an unprecedented level of pollution and threat, Panerai is stepping up to the challenge of doing better.

But the company’s efforts aren’t just limited to the seas; in recent years, Panerai has adopted a suite of new measures to minimise its impact, from a state-of-the-art manufacturing facility in Neuchâtel, Switzerland, to implementing company-wide environmental codes of conduct. Panerai is, veritably, a brand leading the charge towards a better future for the watchmaking industry.

With increasing scrutiny over the sourcing and use of virgin materials, Panerai has made moves to incorporate recycled components collected from rather clever origins. One such example is the Panerai Submersible Mike Horn Edition collection, which comprises two diving timepieces. Named after the renowned explorer (who famously completed a solo journey around the equator without the assistance of motorised transport), the Mike Horn line was introduced at SIHH 2019 and marked a significant milestone for Panerai and the wider world of watchmaking. The collection was the first to use EcoTitanium, which is aviation-grade recycled titanium sourced from old aircraft. According to the company that produces it, recycled titanium produces 100,000 fewer tons of carbon dioxide compared to regular titanium. The material is used across the case, crown protecting device, bezel and case back of both models.

Taking the use of reclaimed materials even further, each watch also bears woven straps made from recycled PET plastic (the kind commonly used to make single-use plastic water bottles). Plastic pollution is one of the gravest challenges faced by the world’s oceans, so it should come as no surprise that Panerai is doing its bit to help reduce the amount of waste that ends up at sea. The packaging for each watch, too, is made of recycled ABS plastic.

Across other timepieces in Panerai’s collection, strict codes of conduct and ethics are adhered to, ensuring raw materials are sourced from the very best suppliers. The company is certified by the Responsible Jewellery Council (RJC), which promotes responsible ethical, social and environmental practices in the production of gold and diamond jewellery. Looking to the Washington Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES) and the Protection Suisse Des Animaux (PSA), Panerai has made big changes when it comes to retrieving leathers. These are now obtained from ethical suppliers and the company has signed a declaration that renounces the use of certain exotic skins.

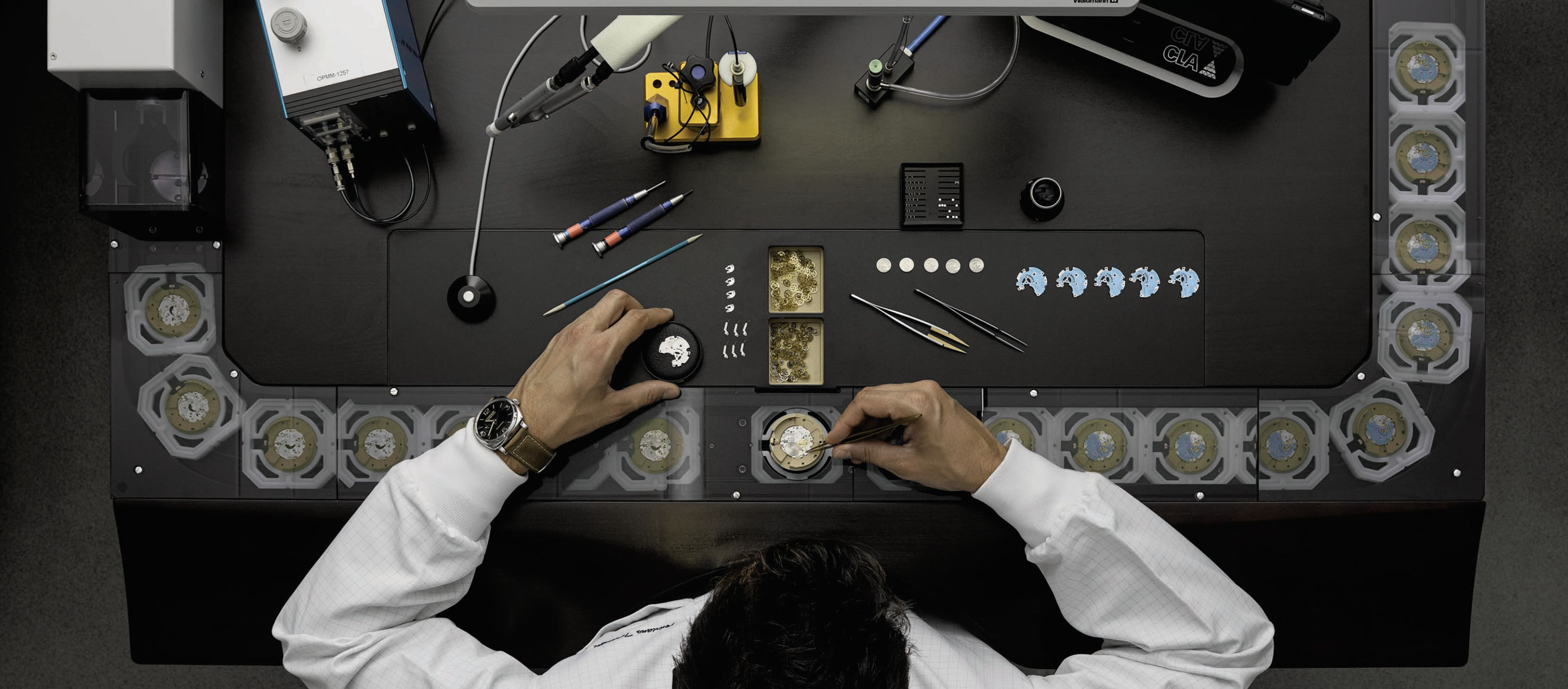

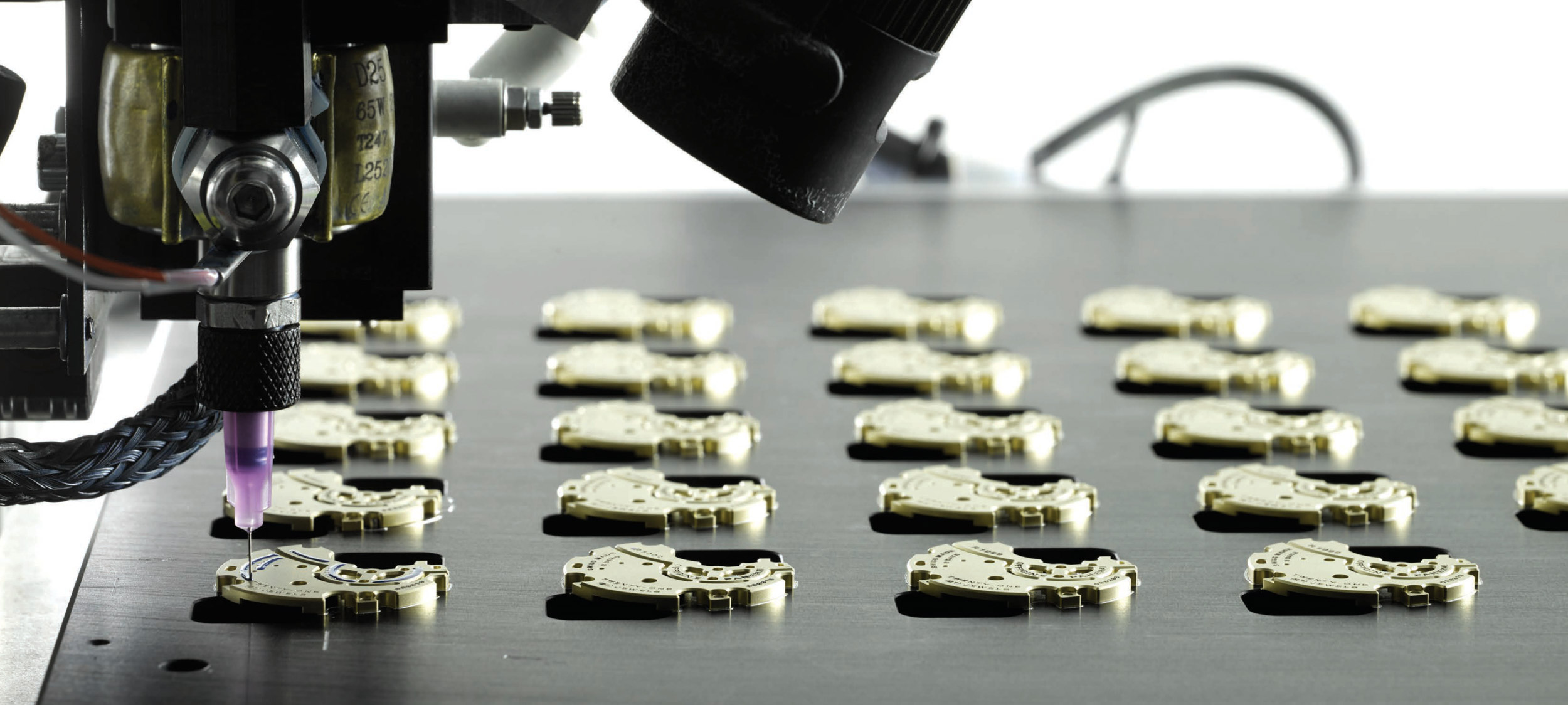

But Officine Panerai’s sustainability initiatives go deeper than the watches it produces. Like other brands in the Richemont Group family (IWC Schaffhausen being just one example), greener practices extend to the company’s headquarters. Located in the heart of Swiss watch-making, Neuchâtel, the company’s primary manufacturing facility is a fantastic example of sustainable design done right. There are several inventive ways various resources are reused throughout the factory to reduce Panerai’s environmental impact. Any water used throughout the watch production process is recycled in the sanitary and cooling systems and for cleaning, and rainwater is collected for the restrooms and facility gardens. Solar panels heat the water used in the restaurant and showers, geothermic sensors and a heat-pump system are employed for heating and cooling, and energy produced by Panerai’s machinery is reused in the facility’s heating system. In fact, no fossil fuels are used for heating and cooling. Hydraulic power is also harnessed to operate much of the facility’s machinery. At a minimum, the company is working to meet Minergie® standards, which identifies low-energy-consumption buildings in Switzerland.

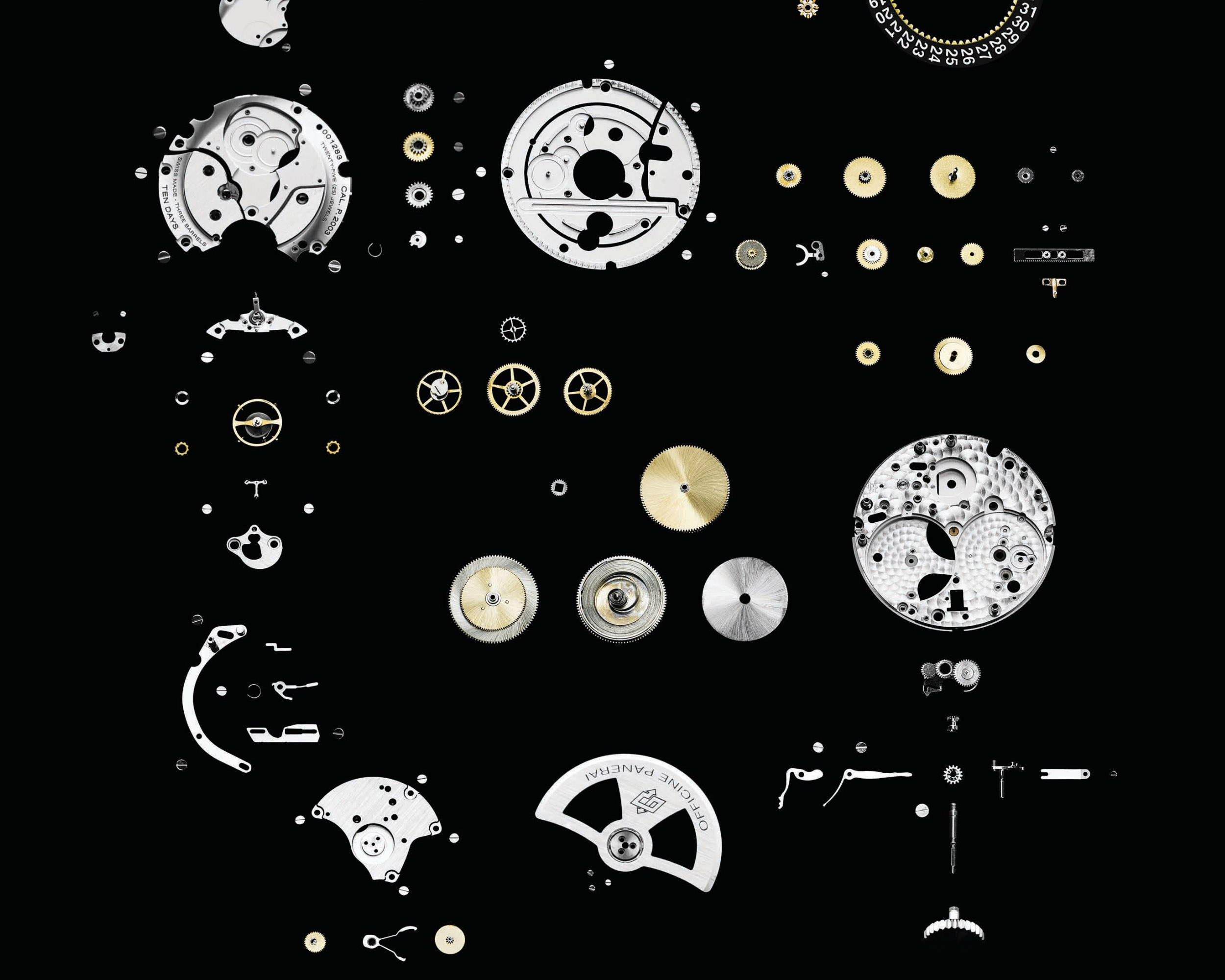

Overall, the facility has zero impact when it comes to its carbon thanks to the impressive steps the company has taken to minimise its footprint. And, with research and development, production and assembly of the brand’s watches all kept in-house at the facility, environmentally sound practices form the core of every arm of the business; sustainable initiatives aren’t just a token addition but a company-wide philosophy.

That ethos extends to the way Panerai encourages staff to adopt more environmentally sound habits through its best-practice guidelines. Printing is discouraged unless absolutely necessary, and any printed materials must be produced on Forest Stewardship Council (FSC) certified paper. The company also advocates the use of public transport and recommends trains over planes when travelling for work. Even smaller acts such as shutting down computers before leaving the office are heavily endorsed. As per the environmental axiom, it’s clear that Panerai has adopted the idea that every bit counts.

It’s commendable to see a company embrace positive actions with such force. By showing how seamless it can be to integrate recycled and ethical materials into beautiful and functional timepieces and encouraging environmentally ethical practices company-wide, Panerai is treading an important path in the watchmaking industry. And with such a robust track record of implementing effective sustainability initiatives, there’s no doubt the company will continue to cement itself as a green trailblazer.